Vacuum Forming

Plastic Vacuum Forming

The Process:

Plastic sheet is heated in an oven

Heated plastic sheet is presented to the mold

Mold is inserted into heated plastic sheet and vacuum is turned on

After the part is formed and cool down process is completed, the part is removed

Now the part is ready for all necessary secondary operations (trimming, drilling, finishing, etc.)

Advantages:

Quick Setup Time

Low Cost Tooling

Economical for low, medium and high production runs

Plastic Vacuum Forming

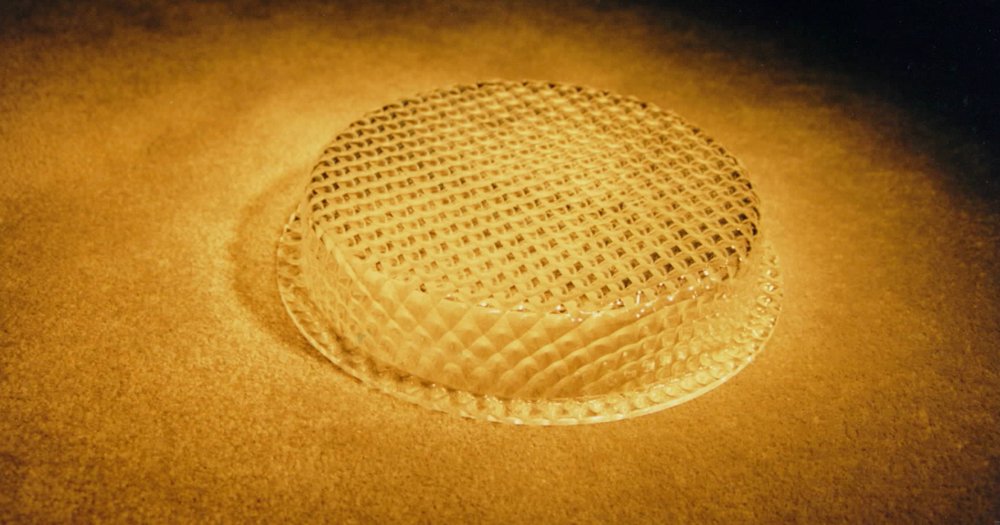

Plastic vacuum forming is ideal for thermoforming various products with intricate details. The suction created from the vacuum-ready tooling allows for the creation of highly-detailed parts, thus creating a sculpture-like product as seen in various lighting fixtures, automobile parts, displays, waterfountains, etc.

“We don’t have competitors, only companions in this industry, that’s why we supply them. That’s why even if your work is sourced from a different vendor, there’s a high probability that we produced it.”