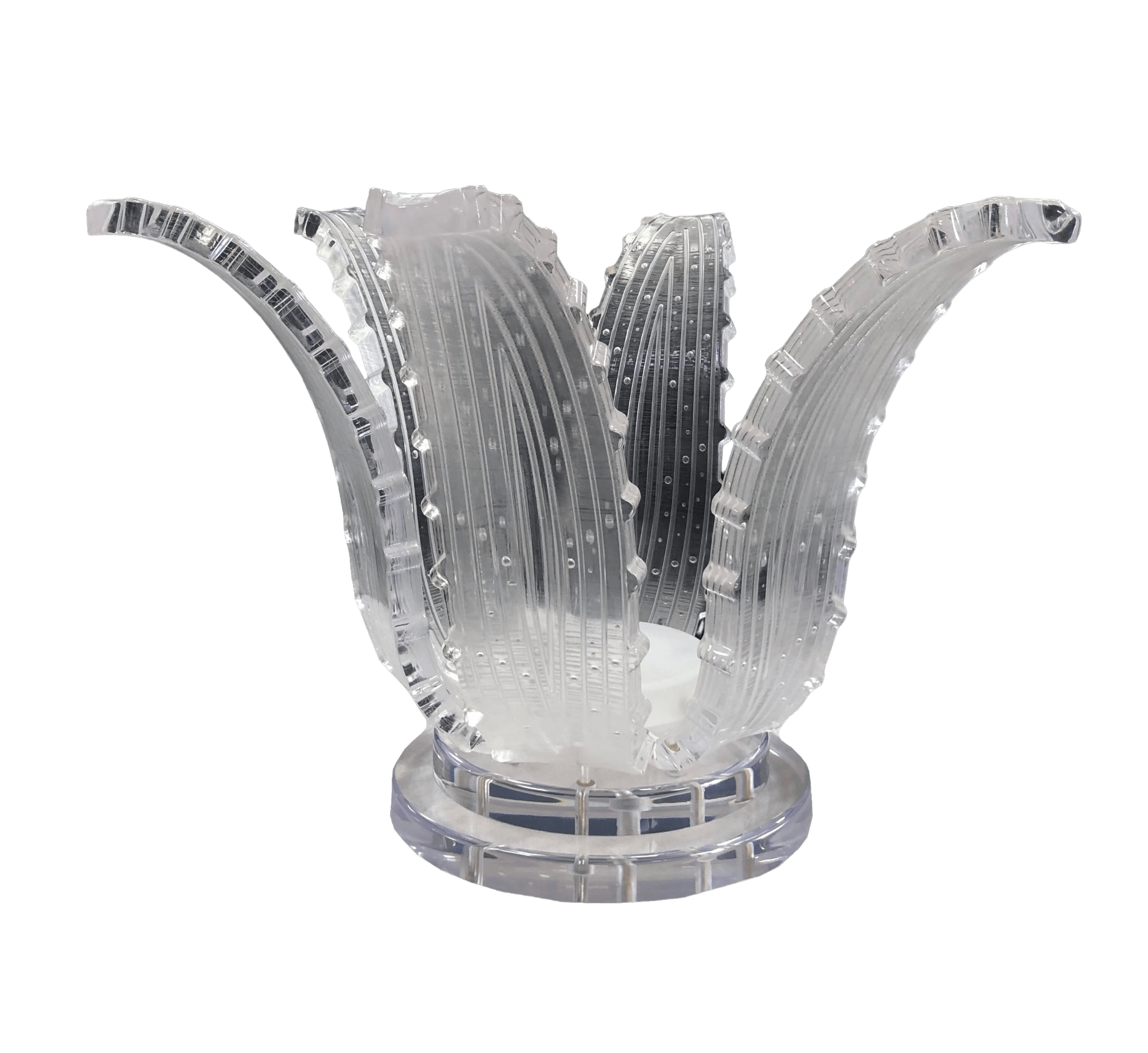

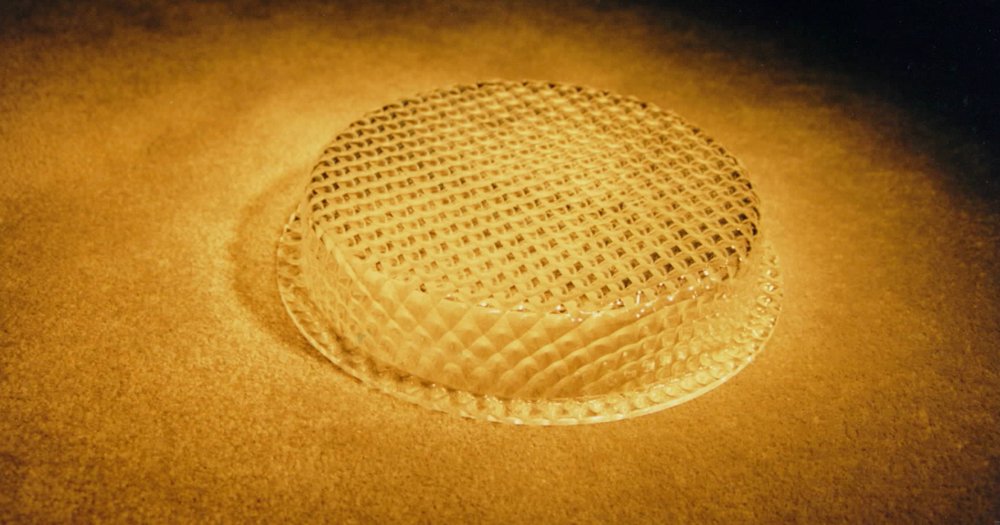

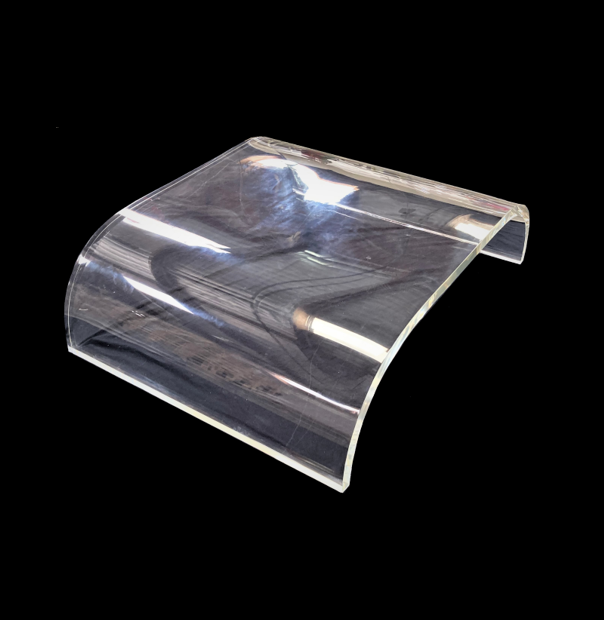

Plastic Thermoforming

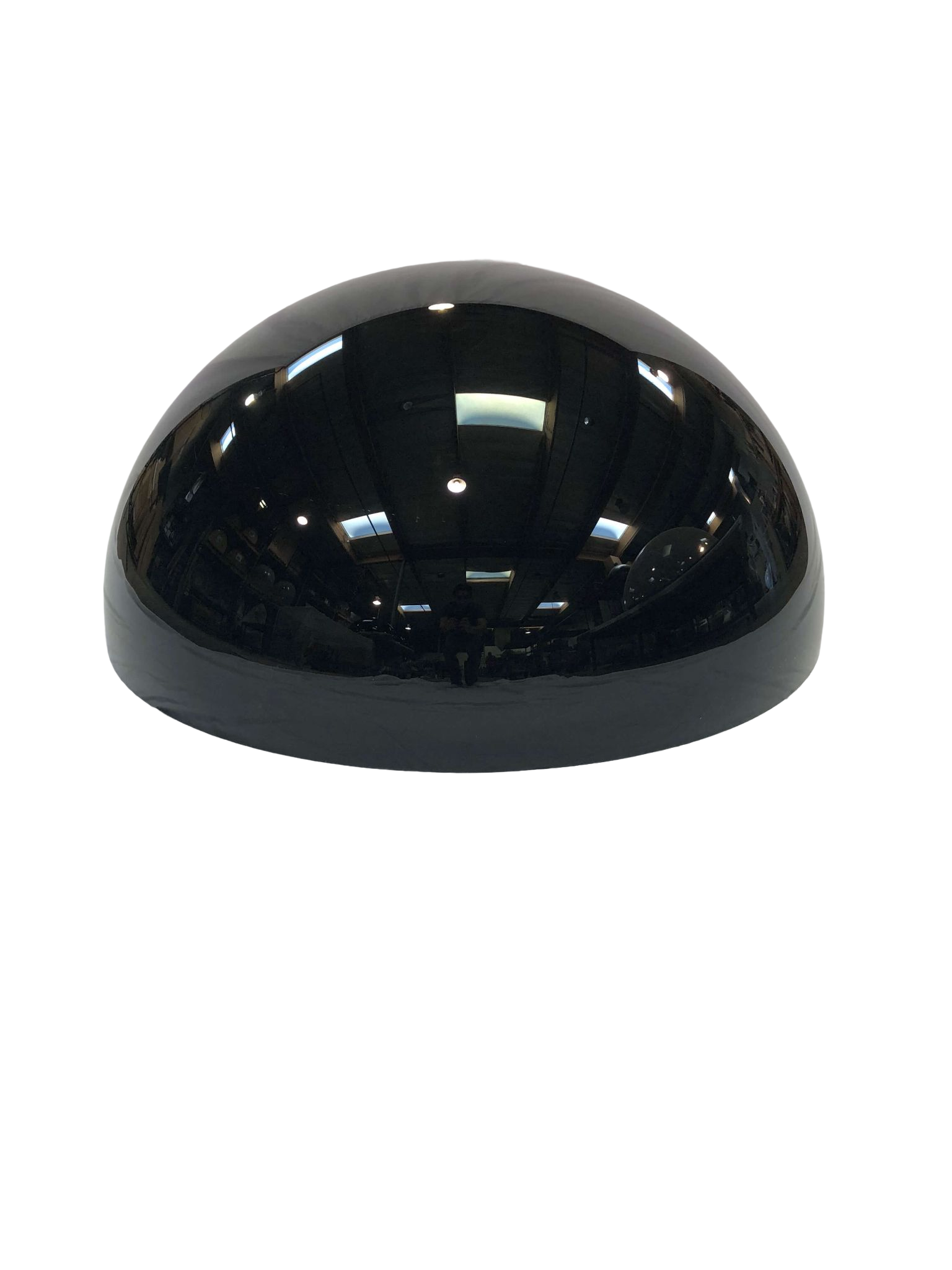

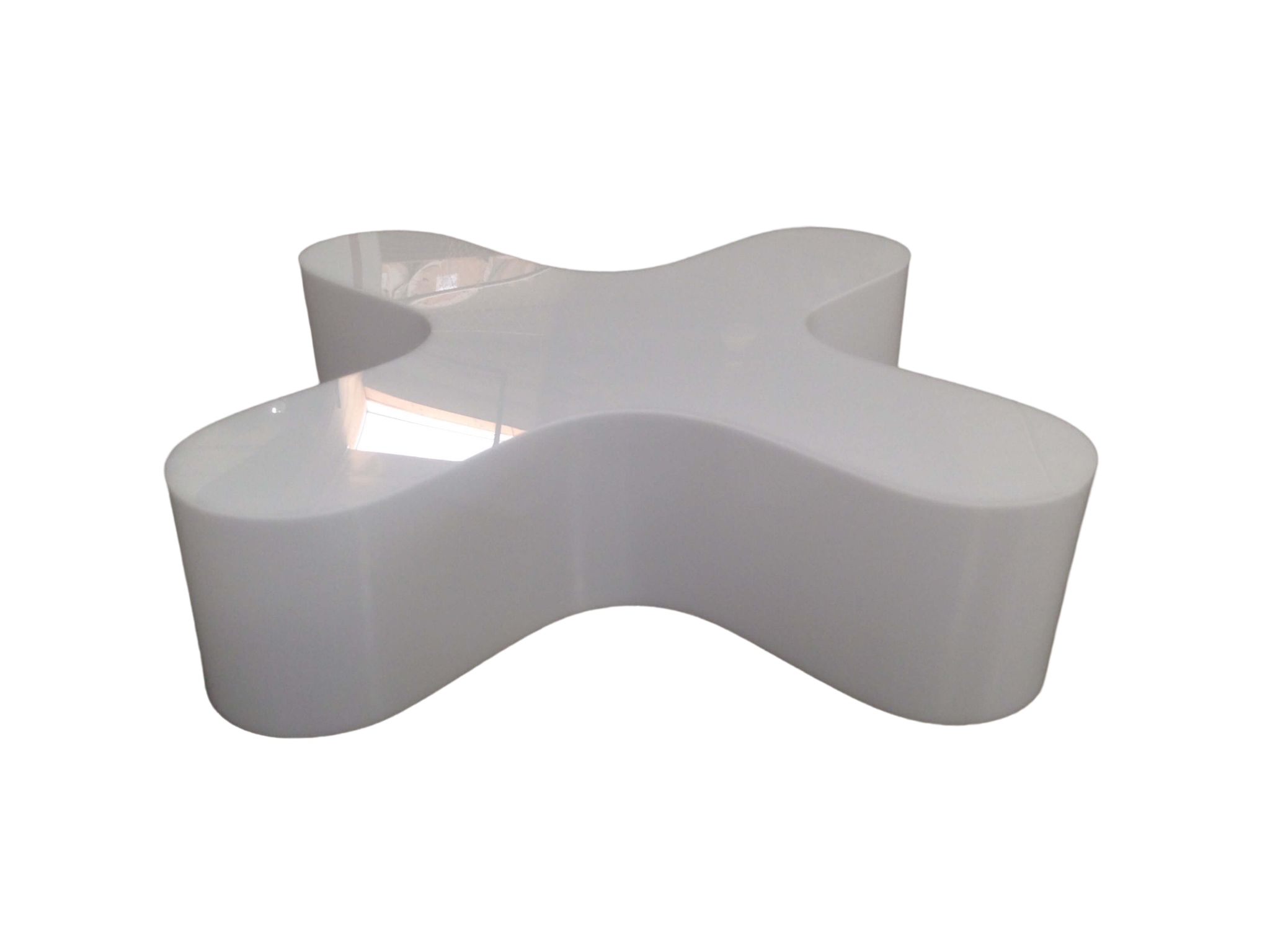

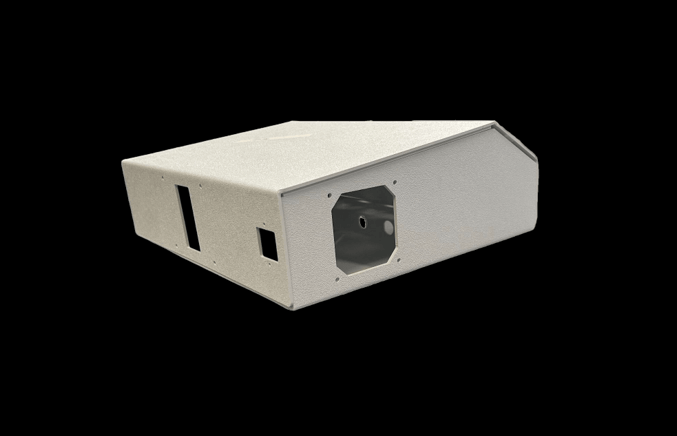

We have thermoformed thousands of different complex parts while maintaining tight tolerances which our customers demand from us. We have thermoformed anything from prototypes up to thousands of parts. Thermoformed parts are evident in practically every industry, and our custom thermoforming process allows us to be flexible in producing various projects in a short amount of time.

We have the ability to process and form through vacuum forming, pressure forming, drape forming, line bending, and blow forming. We are very experienced in every process with highly efficient engineering processes utilized to meet customer deadlines, provide consistent and uniform parts, and maintain low cost.

Plastic Thermoforming Services:

Material selection

Enhancements in part geometry

In-house mold and tooling manufacturing

Model Development

Final Design

Plastic Thermoforming Advantages:

Provides precision part detail

Able to achieve tight tolerances

Flexible tooling and engineering can be achieved in prototypes and (low, medium and high) production runs

Cost effective and efficient setup times

“We don’t have competitors, only companions in this industry, that’s why we supply them. That’s why even if your work is sourced from a different vendor, there’s a high probability that we produced it.”